Switch On the cooling plant or open a loop

- make sure that no alarm is active (ask the DSS station for confirmation)

- navigate the FSM tree, go to spdServices -> spdCooling

- select ON on each loop, allow 30 seconds between each loop opening to let the plant stabilize

- wait ~5 minutes for the cooling to be ready on all the lines.

- usually the used values are 4-4.5 bars liquid pressure and 1.7 bar on the gas side; if you have doubts check with the on call cooling expert which parameters to set.

Correspondance between SPD sectors and loop numbers:

Switch Off the cooling plant or close a loop

- navigate the FSM tree: go to spdServices -> spdCooling

- move each loop to OFF state. Allow 10 seconds between each loop closing

-----------------------------------------------------------------------

Emergencies for cooling system.

- The only not interlocked problem is the presence of liquid in the compressor which happen when the current weight is 8 kg below the value after the recovering.

CHECK PERIODICALLY THE WEIGHT. If too low: stop the test, go to the Stand-by mode and close the open loops.%BR%

In Case Of ALARM

- The interlocked power supplies should be switched OFF. If not, switch OFF all the sectors and heat generators.

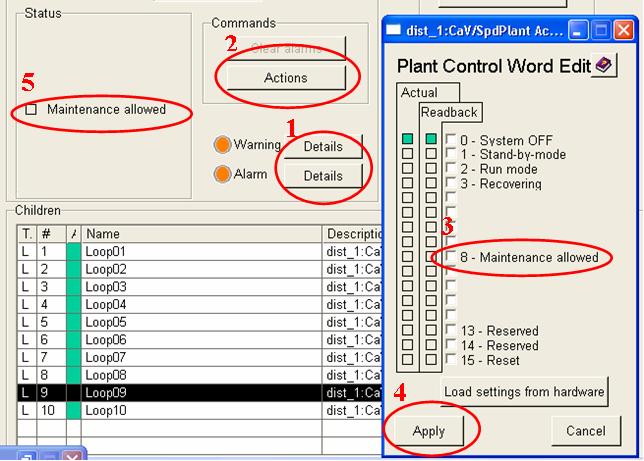

- Click on DETAILS on the PVSS device control (next picture point 1) to identify and solve the problem. If needed, use the [[#CallNumberCooling][telephones number]].

Solved the problem, the system must be reset. ATTENTION: it is possible to reset the system only three times in few minutes, after that the reset button will be blocked for an hour. If after two resets the system goes still in ALARM, please Call the 165453 ( Gianluca Guaglio) in case of troubles or 163313 (Miquel Angelo Pimenta dos Santos) just for emergencies.

To reset the system,

- Click to the ACTIONS (next picture point 2) on the PVSS device control to open the Plan Control Word Editor.

- Activate the maintenance clicking on the corresponding check box (next picture point 3).

- Apply the modification clicking on APPLY (next picture point 4). On the device control, the corresponding status led (next picture point 5) becomes green.

- On the PLC panel, put the system in a proper state. For example, to avoid overpressure in the condenser it is wise to lock all the loops before resetting the system.

- Push < Reset > on the PLC front panel. Wait few minutes (~5) to be sure that there are no other problems.

- In the PVSS interface, it is better to put all the loops in the same configuration of the PLC panel. This to avoid surprises when the control is retaken by the PVSS interface.

- Retake the control of the Cooling deselecting the maintenance check box. Select also the proper status of the system, putting it equal to the PLC one (tipically RECOVERING). Click on Apply and then on CANCEL to close the Plan Control Word Editor.

- The Cooling is now ready again.

Maintenance activation.

After the test.

- Go to RECOVERING mode, if you have to recover a lot of liquid in short time. ATTENTION during the RECOVERING the weight alarm is inhibited for weight incresing. So, generally, is better to go to the STANDBY. It is also better to close the open loops. If the system has to be stopped for several days (>7), after one week of STANDBY put the system in the STOP mode.

Update the logbook with at least the weight (to check possible leaks) when you start, when you finish and record any problem.

Call the 165453 ( Gianluca Guaglio) in case of troubles or 163313 (Miquel Angelo Pimenta dos Santos) just for emergencies.

-- Main.gguaglio - 30 Mar 2006